Vertical exposed mounted fan coil unit

Product features

High efficiency and sufficient energy

The coil is made of high-quality seamless copper tubes and aluminum sine wave pattern heat dissipation fins, which are hydraulically or mechanically expanded. The fins are absolutely tightly connected to the copper tubes, allowing for optimal performance.

High air volume and low noise

Adopting ultra wide angle volute and multi blade centrifugal wind turbine, the wind turbine is reasonably matched with various motors, with low noise, which can meet various needs of the unit.

Safe and reliable, with a long lifespan

The motor is an induction motor with a built-in temperature rise protector, and generally does not burn out unless there are special circumstances; Each unit's coil undergoes high-pressure leak detection to ensure that the unit does not experience water leakage.

Strong adaptability

Widely used in low-noise places such as hotels, office buildings, hospitals, exhibition halls, etc., it can better meet people's requirements for comfort.

Place of use

Widely used in various places such as hotels, theaters, shopping malls, office buildings, schools, warehouses, etc; As an industrial air conditioner, it can also meet the needs of various industries such as electronics, chemical, medical, pharmaceutical, cigarette, food, and light industry.

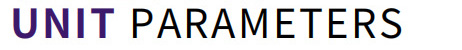

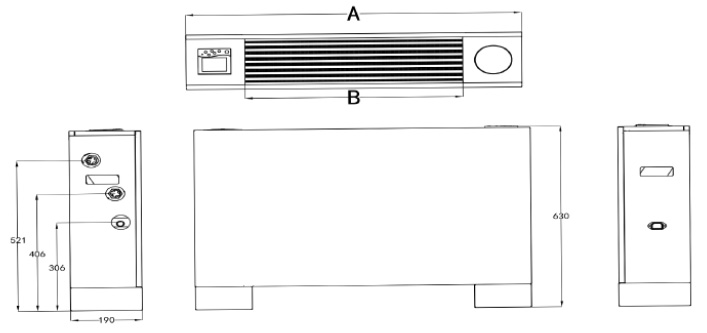

Vertical exposed mounted fan coil unit (two pipes and three rows of pipes) A-direction view

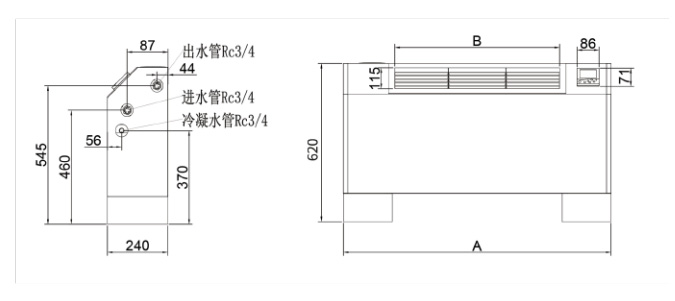

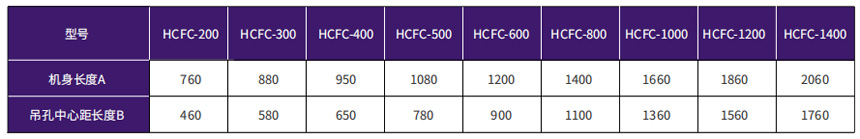

Outline dimension table for vertical exposed mounted fan coil unit (two pipes and three rows of pipes)

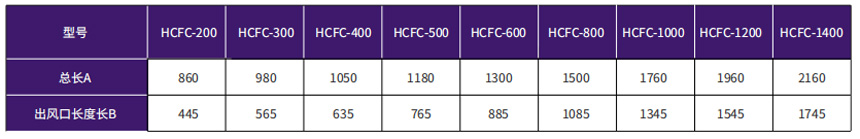

European vertical exposed mounted fan coil unit (two pipes and three rows of pipes) A-direction view

External dimensions of European style vertical surface mounted fan coil unit (two pipe and three row pipe)

A view of the new vertical exposed mounted fan coil unit (two pipes and three rows of pipes) in the A direction

Outline dimension table for the new vertical surface mounted fan coil unit (two pipes and three rows of pipes)

Vertical exposed mounted fan coil unit (two pipe, 3-row pipe, AC motor)

note:

1. Cooling: inlet and outlet water temperature of 7 ℃/12 ℃, inlet air dry bulb temperature DB27.0 ℃, wet bulb temperature WB19.5C.

2. Heating: The inlet and outlet water temperature is 60 ℃/50 ℃, and the inlet air dry bulb temperature is DB21.0 ℃.

3. The noise in the table is measured by the unit in a fully anechoic room with a background noise of 16.5dB (A) (according to GB/T19232-2019).

4. The static pressure at the outlet of the low static pressure compressor group with air outlet and filter is 0Pa; When there is no air outlet and filter, the static pressure at the outlet is 12Pa.

5. The power consumed by the motor load is the input power (also known as reference condition consumption), and the power indicated on the motor nameplate is the nominal power, which is the output power of the motor when operating under rated conditions.

6. If the actual operating conditions are different from the standard operating conditions, please refer to the correction coefficient table data in the sample for correction.

Correction method: Actual cooling (heat) capacity=rated cooling (heat) capacity X working condition correction factor.

7. Our company reserves the right to make product improvements or design changes without prior notice, and all products are based on the actual product.

- Previous:Mural Fancoil Unit

- Next:Vertical concealed fan coil unit